Polymethylpentene Co-Polymer (PMP or TPX) Medical Grade DX845, 200g

- Description

Description

Polymethylpentene (PMP or TPX) Medical Grade DX845

Purity Limit: ≥ 99%

Melting Point: 236°C

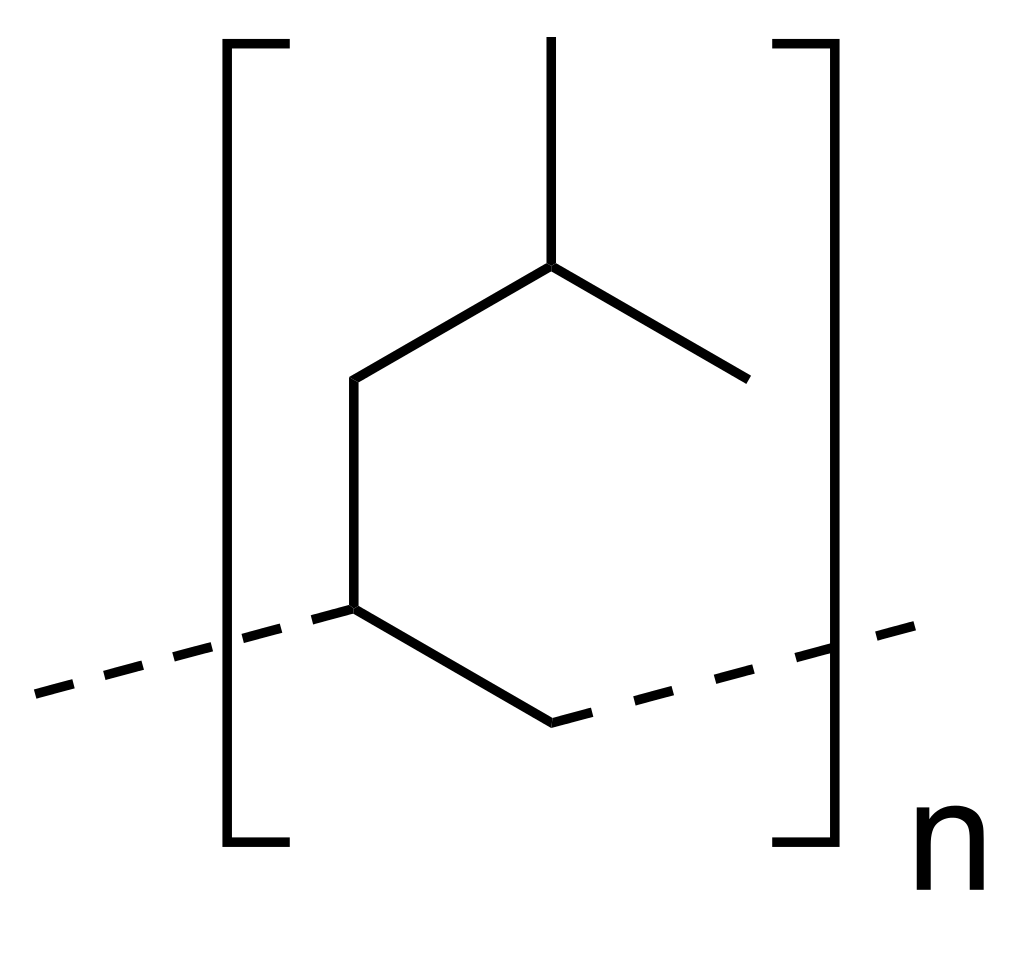

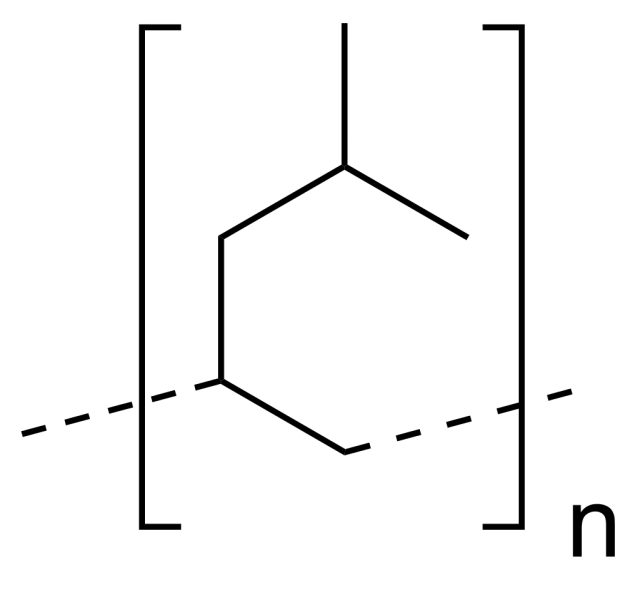

Molecular Formula: (C6H12)n

Density: 0.833 g/cm^3

CAS No: 25068-26-2

Elastic strength: 25 MPa (ASTM D-790)

Izod impact resistance: 98 KJ/m2 (ASTM D-256)

Tensile strength at yield: 25 MPa (ASTM D-638 )

Elastic Modulus: 640 MPa (ASTM D-790)

Tensile modulus: 1863 MPa (ASTM D-638)

Rockwell hardness: R62 (ASTM D-785)

Tensile strength: 20 MPa (ASTM D-638)

Elongation at break: 60 % (ASTM D-638)

Refractive index: 1.463 nd (ASTM D-542)

Light transmittance: 90% (ASTM D-1746 )

SYNONYMS: ME316300, poly(4-methyl-1-pentene)

Polymethylpentene (PMP), also known as poly(4-methyl-1-pentene), is a thermoplastic polymer of 4-methyl-1-pentene. It is used for gas-permeable packaging, autoclavable medical and laboratory equipment, microwave components, and cookware. It is also called TPX. It can be extruded and molded (by injection molding or blow molding).

Polymethylpentene melts at ≈ 236°C. It has a very low density (0.833 g/cm3) and is transparent. It has low moisture absorption, and exceptional acoustical and electrical properties. Its properties are reasonably similar to those of other polyolefins, although it is more brittle and more gas permeable. The polymer also has a high thermal stability, excellent dielectric characteristics and a high chemical resistance. The crystalline phase has a lower density than the amorphous phase.

In comparison to other materials being used for operating in THz range, TPX shows excellent optical properties with a wavelength independent refractive index of 1.460±0.005 between visible light and 100~GHz.

Possible applications:

- It is FDA compliant for use in food processing machinery. Polymethylpentene is often used in films and coatings for gas-permeable packaging.

- Because of its high melting point and good temperature stability, polymethylpentene is used for autoclavable medical and laboratory equipment, microwave components, and cookware.

- Applications include sonar covers, speaker cones, ultrasonic transducer heads, and lightweight structural parts.

- It is also often used in electrical components e.g. LED molds because it is an excellent electrical insulator.

- TPX is a hard, solid material, which can be mechanically shaped into various optical components like lenses and windows. Also specifically TPX is used in CO2 laser pumped molecular lasers as an output window because it is transparent in the whole terahertz range and totally suppresses the ~10 μm pump radiation.